Food Processing & Manufacturing Uniforms

Food Processing & Manufacturing Uniforms That Deliver

In Southern California's bustling food processing industry, the demand for specialized uniforms is on the rise. Many uniform rental suppliers struggle to keep up with the demand, which leaves businesses like yours “fed-up” with surprise charges, incomplete and compromised deliveries, and waiting weeks on end for a reply from their customer service department.

The last thing you need to do in your business is the job of your uniform provider. However, with Kleen Kraft Services, you’re in luck. With seven decades of experience serving leading food processing and manufacturing companies, our uniforms consistently exceed FDA and USDA standards. We also support compliance with HACCP guidelines, minimizing cross-contamination risks and protecting your food supply.

But that’s just the beginning; we outperform national competitors through unbeatable service, responsiveness, and fair billing practices. Let us help you maintain HACCP standards without compromising good, old-fashioned customer service.

HIGH-QUALITY UNIFORM RENTAL PROGRAMS AND FACILITY SERVICES

Serving the greater Los Angeles area since 1952. Contact us today to learn more about our uniform rental services.

Garments That Comply With HACCP Guidelines

Choose from our wide selection of food processing and manufacturing uniform garments. Made for both safety and comfort, they are designed to withstand demanding work environments and intense laundering processes, all while consistently meeting HACCP standards.

Kleen Kraft Services offers a wide range of garments that can be customized for your unique operation, including:

Wrap-Around Smocks

Aprons

Lab Coats

Pocketless Shirts

Cook Shirts

Cook Pants

Our Tried-And-True Laundering Process

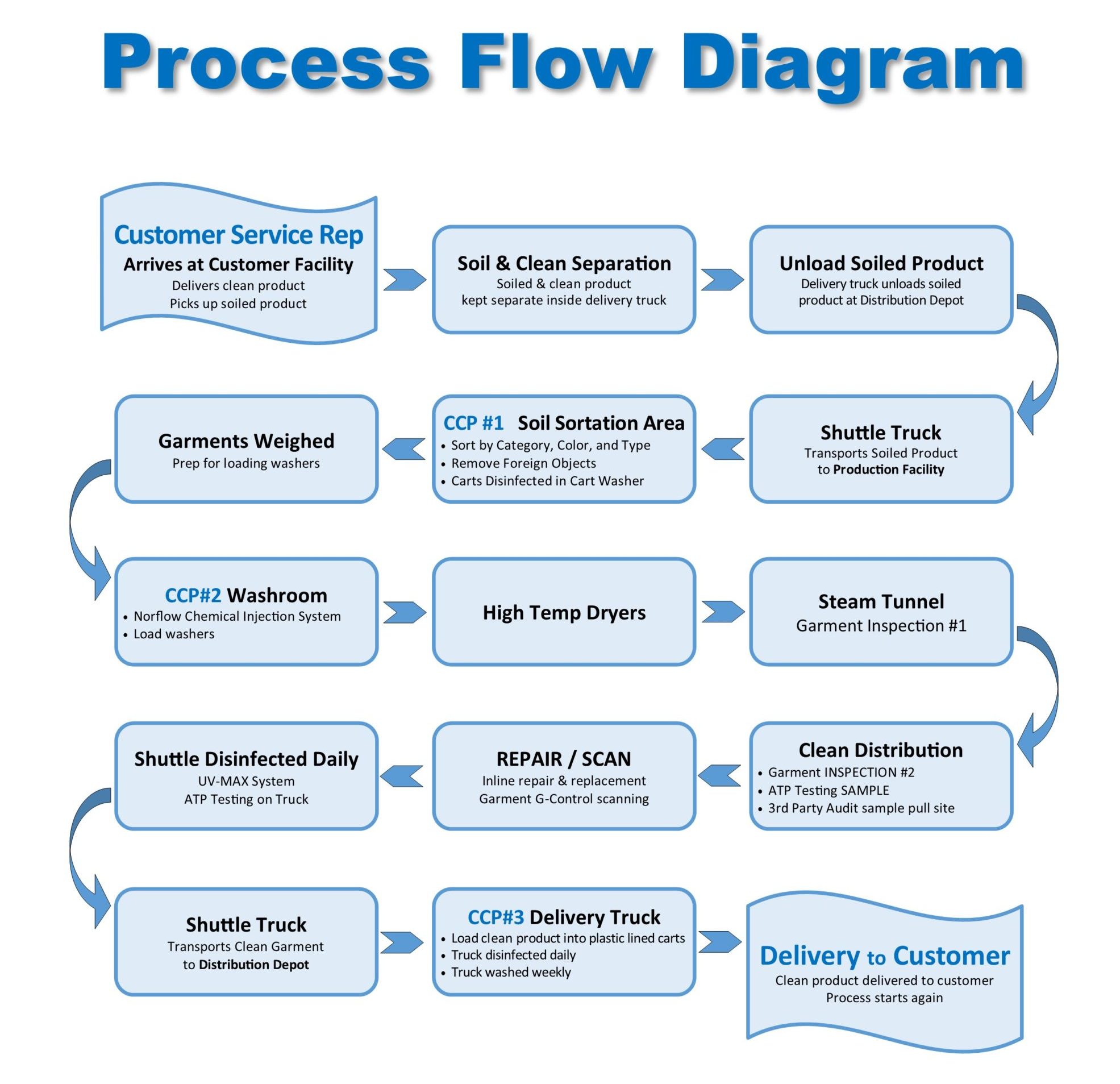

The proper laundering of your uniforms is perhaps the most important step in ensuring hygienically clean garments. Using quality chemicals and processes, we keep garments free of bacteria, and extend their life.

Our Route Service Representatives are trained to handle your uniforms with specialized care, avoiding any cross-contamination between clean and soiled items. We also make sure that the delivery carts for your uniforms are both sterilized and sealed for maximum cleanliness.

Key Factors in the Proper Sanitation of Food Processing Garments

Wash Formulas

Wash Formulas

Wash formulas must be engineered to produce hygienically clean garments that are free from microbial contamination due to bacteria and viruses.

Water Temperature

Water Temperature

An appropriate water temperature during the wash cycle is essential to kill any microorganisms on the garment.

Uniforms That Meet or Exceed HACCP Standards: Safe and Sterile Laundry Process from Start to Finish!

For industrial laundering, HACCP means only one thing to a customer: the prevention of cross-contamination that could impact your product. At Kleen Kraft, we have developed a detailed HACCP Program to ensure you have hygienically clean garments that are free of bacteria and viruses, as well as chemical and physical hazards.

Any garment that is worn inside a food processing or manufacturing plant is considered a “food surface.” That’s why your uniform garments are an integral part of the food safety process.

Kleen Kraft Is Hygienically Clean Certified In Food Safety

Kleen Kraft Services is committed to excellence and has earned the Hygienically Clean Certification in Food Safety from the Textile Rental Service Association (TRSA) for our food processing uniforms. This certification shows our dedication to keeping your food production lines clean and safe.

Kleen Kraft consistently passes the three rounds of quantified biological testing as required by an accredited laboratory, verifying that our laundry processes are producing Hygienically Clean Food Safety uniform garments that meet internationally recognized hygiene standards.

Microbial testing provides tangible proof that our garments are free of mold, yeast, viruses, and bacteria, including E-coli, Salmonella, Candida, Staph, and others.

To receive the certification, Kleen Kraft additionally underwent a comprehensive, third-party inspection that confirmed essential evidence that:

Products & Supplies for Your Food Processing Facility

You can count on us for more than flexible, hygienically clean food processing uniforms. We also offer a variety of facility service products specially designed for the unique demands of the food processing and manufacturing sector.

Our facility service products include floor mats, mops, towels, hand soaps & sanitizers, as well as paper product fulfillment.

Request A Quote For HACCP Food Processing And Manufacturing Uniforms

With decades of experience servicing food-processing plants of every size throughout Southern California, we have the capacity and inventory to provide everyone in your company—from the production line workers to lab technicians—with top-of-the-line uniforms that are safe, sterile, and durable.

When you work with Kleen Kraft, you’re partnering with a uniform supplier that prioritizes quality garments, responsive and helpful customer service, and a friendly face in your route service representative that you can count on for years to come.

If you’re ready to work with the accountable uniform company, let’s have a conversation.

Affiliations & Certifications

As part of our commitment to continuous improvement, Kleen Kraft Services is certified as a Hygienically Clean Food Safety provider and is certified as a State of California SBE. We are a member of the industry associations TRSA and CSCNetwork.